How Generators Work: Powering Our World through Mechanics

Imagine a world suddenly plunged into darkness, silent except for the distant hum of… nothing. No lights, no devices, no digital pulse. This isn't just a dystopian fantasy; it's a stark reminder of our profound reliance on electricity, and at the heart of its creation lies a marvel of engineering: the generator. Understanding How Generators Work: The Mechanics of Power Production isn't just for engineers; it's about appreciating the invisible forces that shape our modern existence.

Generators, in their essence, are the unsung heroes translating raw energy into the clean, usable electricity that lights our homes, powers our industries, and connects our lives. They're a testament to humanity's ingenuity in harnessing fundamental physical laws to meet an ever-growing demand for power.

At a Glance: Decoding the Generator's Magic

- Energy Transformation: Generators don't create energy; they convert it. Think of them as sophisticated translators, changing mechanical energy (from steam, wind, water, or fuel combustion) into electrical energy.

- The Core Principle: It all boils down to Michael Faraday's discovery of electromagnetic induction: moving a conductor through a magnetic field (or vice versa) generates an electric current.

- Key Components: A generator typically consists of a stationary magnetic field (stator), a rotating coil (rotor), and a prime mover (the engine providing the mechanical spin).

- Synchronicity is Key: Before a generator can feed power into a larger grid, its output must perfectly match the grid's frequency, phase, and voltage—a process called synchronization.

- Constant Evolution: From early steam engines to modern smart grids and hybrid systems, generator technology continually advances, driven by the quest for greater efficiency and sustainability.

- Vital Applications: From massive hydroelectric dams powering entire regions to portable diesel units keeping vital services online, generators are indispensable across every sector.

The Heartbeat of Power: Understanding the Generator's Role

For centuries, humanity dreamed of readily available power. The turning point arrived with brilliant minds like James Watt, whose steam engine in the early 19th century laid the groundwork for large-scale mechanical work. But it was Michael Faraday's groundbreaking discovery of electromagnetic induction in 1831 that truly unlocked the door to electric power generation. This led directly to the first electric generator, paving the way for visionaries like Thomas Edison to establish commercial power stations. Today, nuclear power plants and gas turbines stand as further milestones in this relentless pursuit of efficient power.

At its core, a generator is a machine that performs a miraculous energy conversion. It takes various forms of energy – the furious heat from burning fossil fuels, the controlled might of nuclear reactions, or the graceful dance of renewable resources like wind and water – and transforms them into the electricity we depend on. If you're looking to learn about generator definition, you'll find it’s fundamentally about this incredible conversion process.

The Engine Room: Core Principles Behind Power Generation

Behind every whirring turbine and buzzing generator lies a fascinating interplay of scientific principles. Understanding these fundamentals helps demystify the complex dance of power production.

1. Energy Conversion: The Ultimate Translator

Generators are master translators. They don't create energy, as the laws of physics dictate energy cannot be created or destroyed. Instead, they transform it. A steam turbine converts the thermal energy from burning fuel into mechanical rotation. A wind turbine converts the kinetic energy of moving air into mechanical rotation. The generator then takes that mechanical rotation and, through electromagnetism, converts it into electrical energy. This elegant chain of conversion is fundamental to all power generation.

2. Thermodynamics: Mastering Heat and Energy

In many power plants, the journey to electricity begins with heat. Thermodynamics, the study of heat and energy transfer, is crucial here. Whether it's burning coal, gas, or harnessing nuclear fission, the goal is often to generate steam. This superheated, high-pressure steam then drives a turbine. The principles of thermodynamics dictate how efficiently this thermal energy can be converted into mechanical work by the turbine, making it a critical factor in a power plant's overall efficiency. Every effort to minimize energy loss is a battle won for thermodynamic optimization.

3. Dynamics: The Forces of Motion

Once a turbine is spinning, dynamics comes into play. This branch of mechanics analyzes the forces and torques in moving systems. It's essential for designing turbines that can withstand immense speeds and pressures, and for ensuring the smooth, stable rotation of the generator's internal components. From the carefully balanced blades of a wind turbine to the massive rotors inside a power plant generator, dynamics ensures these systems operate reliably and efficiently, resisting the constant stresses of rotation.

4. Vibration Analysis: The Silent Guardian

Machines in power generation operate under extreme conditions, and any uncontrolled oscillatory motion or "vibration" can lead to catastrophic failure. Vibration analysis is the study of these motions, crucial for maintaining machine stability and longevity. Engineers continuously monitor vibrations in turbines and generators to detect early signs of wear, misalignment, or imbalance. This proactive approach prevents costly breakdowns, ensuring the machinery operates safely and extends its operational life.

From Motion to Electricity: The Step-by-Step Generator Process

So, how does all this theory translate into the flick of a light switch? Let's walk through the mesmerizing process of how a generator actually works, step by step.

1. Generating a Magnetic Field: The Invisible Force

The journey begins with the creation of a powerful magnetic field. Inside every generator is a stationary component called the stator. Embedded within the stator are electromagnets, which are essentially coiled copper wires. When an electric current is passed through these coils, they become magnets, creating a strong and consistent magnetic field. This field is the invisible stage where the magic of electricity generation will soon unfold.

2. Mechanical Energy Input: The Prime Mover Takes Charge

Next, we need something to spin. This "something" is called a prime mover. It's the engine that provides the initial mechanical energy. Prime movers come in many forms:

- Steam Turbines: Driven by high-pressure steam (from burning fossil fuels, nuclear reactions, or concentrated solar power).

- Gas Turbines: Powered by burning natural gas or other fuels directly, with exhaust gases spinning the turbine.

- Water Turbines: Used in hydroelectric plants, where the force of falling water spins the turbine.

- Wind Turbines: Harnessing the kinetic energy of wind.

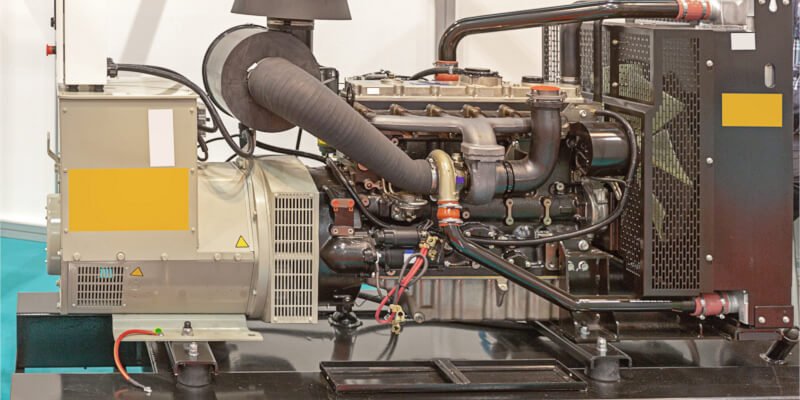

- Internal Combustion Engines: Typically diesel or natural gas engines, often used for smaller generators or backup power.

The prime mover is connected to the generator's central shaft, ready to set its internal components into motion.

3. Electromagnetic Induction: Faraday's Genius at Work

Now for the core principle. The rotating shaft, driven by the prime mover, spins another key component within the generator: the rotor. The rotor itself contains conductive coils. As the rotor spins within the stator's magnetic field, its windings cut through the invisible magnetic field lines. This cutting action is precisely what induces an alternating voltage in the rotor's coils. This phenomenon, discovered by Michael Faraday, is known as Faraday’s Law of Electromagnetic Induction. It's the fundamental principle that transforms mechanical movement into electrical potential.

4. Power Output: Delivering the Current

The induced alternating voltage in the rotor's windings doesn't stay there. It generates an alternating current (AC). To get this AC out of the spinning rotor and into an external circuit, specialized components called slip rings and brushes are used. The slip rings rotate with the rotor, while stationary brushes maintain continuous contact, allowing the current to be extracted.

AC is the preferred form for most electrical power transmission and distribution because it can be easily stepped up or down in voltage. The common frequencies of AC power, such as 50 Hz or 60 Hz, are precisely determined by the speed at which the generator shaft spins and the number of magnetic poles in the stator.

5. The Excitation System: Maintaining the Magnetic Force

For the generator to produce a consistent and stable output voltage, the magnetic field in the rotor needs to be precisely controlled. This is the job of the excitation system. It essentially provides a continuous direct current (DC) to the rotor's field windings, establishing and maintaining that crucial magnetic field.

Initially, a small current from an external source might be used to "kick-start" the field. Once the generator is running, the excitation system continuously adjusts this current. It often includes a voltage regulator that monitors the generator's output voltage and makes fine-tuned adjustments to the excitation current, ensuring the generator delivers power at a constant, stable voltage, regardless of minor fluctuations in demand.

6. Synchronization: Joining the Grid

Before a generator can connect to a vast electrical grid (or even parallel with other generators), it must be perfectly synchronized. This isn't a suggestion; it's an absolute necessity. The generator's output—its frequency, phase angle, and voltage—must precisely match those of the existing grid.

Synchronizers are sophisticated devices that monitor these parameters. They allow utility operators to fine-tune the generator's speed and excitation until it's perfectly aligned. Once these conditions are met, circuit breakers can be closed, seamlessly connecting the generator to the grid. Failing to synchronize correctly can cause massive power surges, equipment damage, or widespread outages.

7. Power Supply to Load: Meeting Demand

Once synchronized, the generator officially joins the power supply network. It immediately begins supplying power, adjusting its output current and voltage to meet the ongoing electrical demand, or "load." The prime mover plays a crucial role here, too. As the electrical load on the generator changes (e.g., more factories turn on, or more homes switch on their air conditioning), the prime mover responds by adjusting its mechanical input to maintain a stable output voltage and frequency. This dynamic balance ensures the power supply remains consistent and reliable, even as demand fluctuates throughout the day.

This intricate, continuous cycle of mechanical motion, magnetic fields, and electron flow is what keeps our modern world lit and running.

Beyond the Basics: Advanced Generator Concepts & Technologies

The quest for more efficient, reliable, and sustainable power never ends. Modern generators incorporate advanced concepts and are at the forefront of ongoing research.

Efficiency: The Holy Grail of Power Production

Efficiency is paramount in power generation, defined as the ratio of useful output energy to input energy. Even small percentage gains can save massive amounts of fuel and reduce emissions. Modern generators and power plants employ sophisticated designs, advanced materials, and precise control systems to maximize this ratio. For instance, combined cycle gas turbines achieve high efficiencies by using the hot exhaust gases from a gas turbine to generate steam for a second steam turbine, effectively getting "double duty" from the fuel.

Load: The Pulse of Demand

"Load" refers to the demand for electrical power from a system. Managing the load is critical for grid stability. Generators must be able to quickly adjust their output to match fluctuating demand. Base-load generators (like nuclear or large coal plants) run continuously at high capacity, while peak-load generators (like gas turbines or hydro plants) can be brought online quickly to meet surges in demand. The ability to forecast and respond to load changes is a sophisticated art and science.

The Challenges Ahead: From Wear to Waste

Traditional power generation faces several technical challenges:

- Efficiency Losses: No system is 100% efficient; some energy is always lost as heat.

- Wear and Tear: Mechanical components endure immense stress, leading to maintenance needs and eventual replacement.

- Environmental Impact: Conventional methods, particularly those burning fossil fuels, contribute to greenhouse gas emissions and pollution.

Charting a New Course: Advanced Topics & Future Trends

Engineers and scientists are relentlessly pursuing solutions to these challenges, pushing the boundaries of generator technology.

Recent Research & Innovations:

- Smart Grids: These intelligent networks use digital communication technology to detect and react to local changes in energy demand and supply, optimizing electricity distribution, improving reliability, and integrating renewable sources more effectively.

- Advanced Materials: The development of high-strength, lightweight, and heat-resistant materials (e.g., ceramics, advanced alloys, composites) is leading to more efficient turbines and generator components that can operate at higher temperatures and pressures, extending their lifespan and boosting performance.

- Artificial Intelligence (AI): AI is being deployed for predictive maintenance (identifying potential failures before they occur), optimizing generator operation for peak efficiency, and better forecasting energy demand.

Future Trends: The Power Landscape of Tomorrow:

- Decentralized Power Systems: Moving away from large, central power plants towards localized units (e.g., rooftop solar, small-scale wind, micro-grids). This reduces transmission losses and improves grid resilience.

- Energy Storage Solutions: Advanced batteries (lithium-ion, flow batteries), compressed air energy storage, and pumped-hydro storage are vital for integrating intermittent renewable energy sources, ensuring a stable power supply even when the sun isn't shining or the wind isn't blowing.

- Hybrid Systems: Combining multiple energy sources (e.g., solar and wind with battery storage, or even traditional generation with renewables) to create more robust, reliable, and environmentally friendly power solutions.

Generators in Action: Real-World Applications

Generators are ubiquitous, powering everything from remote villages to sprawling metropolises.

Industrial Power Generation

Manufacturing plants rely heavily on consistent power. Large-scale industrial operations often utilize steam and gas turbines, integrated into their facilities to provide the immense electrical demand needed for continuous production. In mining operations, where grid access can be limited, robust diesel generators are common, increasingly supplemented or replaced by renewables to reduce fuel costs and environmental impact.

Renewable Energy: Tapping Nature's Power

The shift to sustainable power has put generators at the forefront of renewable energy technologies:

- Wind Turbines: Convert the kinetic energy of wind into mechanical rotation, which then drives a generator.

- Hydroelectric Plants: Utilize the potential energy of water stored at height. As water flows downwards, it spins massive turbines connected to generators. The Three Gorges Dam in China stands as the world's largest hydroelectric power station, a colossal example generating approximately 22,500 megawatts.

- Solar Power: While solar panels (photovoltaic cells) directly convert sunlight into electricity without a mechanical generator, they are often paired with battery storage and inverters, which can be seen as part of a larger power generation and delivery system.

Navigating the Power Landscape: Challenges and the Path Forward

Despite their incredible utility, generators and power generation systems face continuous hurdles.

Technical Roadblocks:

- Efficiency Losses: Energy conversion is never perfect; heat losses are inherent.

- Wear and Tear: High-speed rotation and extreme temperatures degrade mechanical components over time, requiring stringent maintenance.

- Environmental Impact: While improving, traditional methods still grapple with the byproducts of fuel combustion and waste.

Innovative Solutions on the Horizon:

- Improved Materials: The ongoing development of superalloys and advanced composites aims to create components that are lighter, stronger, and more resistant to wear and heat, leading to longer lifespans and higher efficiencies.

- Energy Efficiency Technologies: Innovations like advanced heat recovery systems and more aerodynamic turbine designs are continuously improving how much useful energy can be extracted from a given fuel source.

- Increased Renewable Energy Integration: The strategic integration of wind, solar, and hydro power directly addresses environmental concerns and diversifies energy sources, making grids more resilient.

Further Research Frontiers:

- Advanced Simulation Techniques: Sophisticated computer models allow engineers to design and test new generator and turbine concepts virtually, optimizing performance before physical prototypes are even built.

- Nanotechnology for Component Efficiency: Research into materials at the nanoscale promises new coatings and structures that can drastically reduce friction, enhance conductivity, and withstand extreme conditions, boosting efficiency across the board.

- Energy Harvesting from Waste: Exploring methods to convert waste heat, vibrations, or even low-grade chemical energy into usable electricity, tapping into previously lost resources.

Empowering Your Understanding: Key Takeaways for the Future of Power

Generators are far more than just machines; they are the heart of our electrified world, a testament to scientific principle put into practical, powerful action. From the intricate dance of electromagnetic induction to the global network of synchronized power grids, their operation is a symphony of engineering.

As we look to the future, the evolution of generators will continue to be critical. The drive towards greater efficiency, reduced environmental impact, and seamless integration of diverse energy sources will shape how we power our homes, industries, and aspirations. Understanding their mechanics provides not just technical insight but also a deeper appreciation for the ingenuity that keeps our modern world humming along. The future of power generation, driven by continuous innovation, promises a world that is not only brighter but also cleaner and more resilient.